Blog

How to Choose the Best Wire Mesh Weaving Machine?

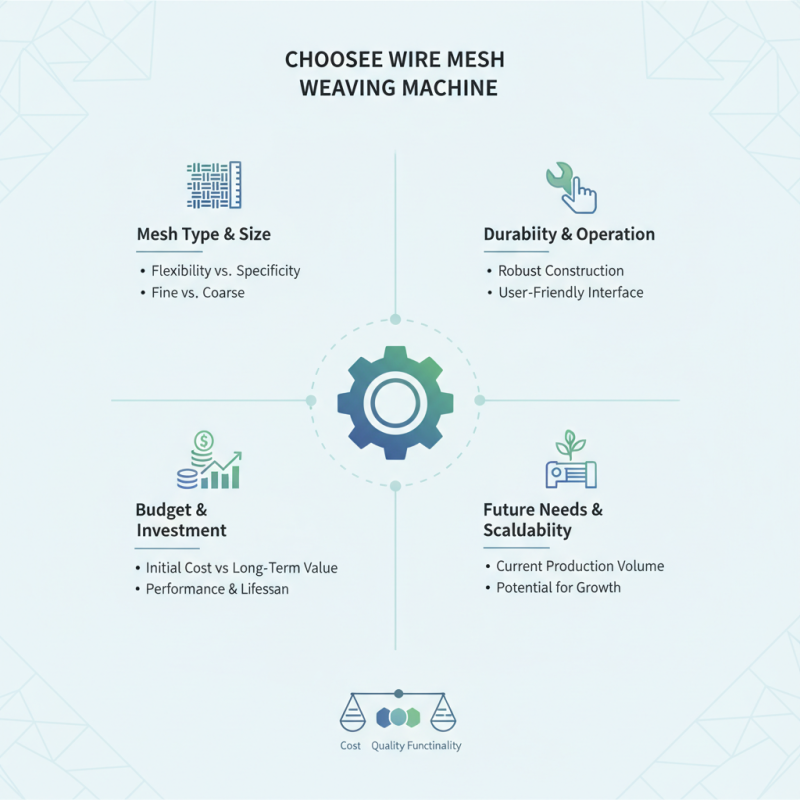

Choosing the right wire mesh weaving machine is crucial for your production needs. The market offers a variety of machines, each with unique features. It's important to understand what you require for your specific application.

Many factors influence the decision. The size and type of mesh you intend to produce matter significantly. Some machines offer flexibility, while others are designed for specific tasks. Durability and ease of use are also vital considerations. A machine that’s too complex may lead to operational challenges.

Consider your budget as well. High-quality machines are an investment but can affect your bottom line. Yet, lower-cost options might not provide the necessary performance or longevity. Reflect on your current needs and future plans. Balancing cost, quality, and functionality is key in selecting the best wire mesh weaving machine.

Factors to Consider When Selecting Wire Mesh Weaving Machines

Choosing the right wire mesh weaving machine is crucial. Several factors come into play. Start with the machine's weaving technique. Different machines use varied techniques like plain weave or twill. Each method produces mesh with specific properties. Think about what you need the mesh for. Is it for construction, filtering, or fencing?

Next, consider the machine's capacity and speed. Some machines can handle larger volumes but may sacrifice precision. Balancing speed with quality can be tricky. Look for user feedback on how machines perform in real-world applications. A machine that appears efficient might not meet your expectations.

Don’t overlook maintenance needs. Some machines require consistent adjustments and parts replacements. This can affect your workflow. Consider how easy it is to access parts and services. Lastly, reflect on your budget. A high-priced machine might not always be the best choice. Weigh the cost against features and reliability. Making a decision can be overwhelming, so take your time to analyze and explore options available to you.

Understanding Different Types of Wire Mesh and Their Applications

Wire mesh is a versatile material used in various industries, including construction, agriculture, and manufacturing. Understanding the different types of wire mesh helps in selecting the appropriate weaving machine. For instance, welded wire mesh is popular for fencing and reinforcement. In contrast, woven wire mesh is often used for filtration and sieving. A survey reported that over 40% of wire mesh applications fall into construction and landscaping.

The material type also plays a crucial role. Stainless steel wire mesh is favored for its durability and corrosion resistance. According to industry data, 30% of users prioritize maintenance-free solutions. On the other hand, galvanized wire mesh is more cost-effective but might require more upkeep. This nuance can impact machine selection as not all machines effectively handle all wire types.

In addition to material, mesh size requirements vary significantly. Fine mesh is essential in filtering applications. Coarse mesh is used for reinforcement purposes. A report indicates that 25% of manufacturing sectors are shifting toward finer mesh for improved quality. This trend calls for advanced weaving machines that ensure precision and versatility. However, not every machine meets these evolving needs, prompting reflection on future investments.

Key Specifications of Wire Mesh Weaving Machines to Evaluate

When selecting a wire mesh weaving machine, certain key specifications warrant careful evaluation. The machine's weaving width is crucial. It affects the size of the mesh produced. A larger width can increase productivity but may require more space. However, a smaller width might offer flexibility for smaller projects. You should consider how this fits into your production goals.

Another important aspect is the machine's speed. A faster machine can elevate output significantly. However, this does not always guarantee quality. Balancing speed and quality is vital. Take note of the adjustable speed settings. This feature can help in customizing the production based on varying requirements.

Moreover, examine the machine’s compatibility with different wire types. Certain machines work better with specific materials. This could limit versatility. Ensure you can adapt to various wire gauges and coatings. It's crucial to understand the maintenance needs as well. Frequent breakdowns can disrupt production. Analyzing these specifics will help in making a more informed choice.

Market Trends and Innovations in Wire Mesh Weaving Technology

In recent years, the wire mesh weaving industry has experienced significant innovations. According to a market analysis by Technavio, the global wire mesh market is expected to grow by nearly $2.5 billion from 2021 to 2025. This growth is driven by technological advancements in weaving techniques and materials. As manufacturers adopt more automated solutions, efficiency increases. However, some companies struggle to keep up with these trends.

One notable innovation is the use of digital weaving technology. This enables precise patterns and customization. Reports suggest that businesses integrating digital solutions see a 20-30% reduction in production time. While this sounds promising, the adoption cost is a challenge for smaller enterprises. They often find it hard to invest in new machinery without guaranteed returns.

In addition, sustainability has emerged as a major concern. The industry is moving towards using eco-friendly materials and processes. According to a study by Grand View Research, eco-friendly wire mesh products are gaining traction, poised to capture more market share. Yet, there's a noticeable gap between innovation and actual practice. Many producers still rely on outdated methods that may compromise environmental goals. Addressing this gap is crucial for future growth.

Market Trends in Wire Mesh Weaving Technology

Cost Analysis: Budgeting for Wire Mesh Weaving Machine Purchases

When considering the purchase of a wire mesh weaving machine, budget is a crucial factor. Industry reports suggest that high-quality machines typically range from $15,000 to $100,000. The significant price variation often stems from features and capabilities. A basic model may suffice for small operations, while larger manufacturers might need advanced machinery. Understanding your production needs is essential.

Maintenance costs can also add to the budget. Regular upkeep can be a hidden expense. Reports indicate that businesses should set aside about 10-15% of the initial machine cost annually for maintenance. This can prevent unexpected breakdowns. Some operators overlook this aspect, which can lead to costly downtimes.

Training staff is another area that requires financial consideration. An effective training program can cost around $2,000 to $5,000 per employee. A well-trained team can enhance productivity and machine efficiency. However, investing in training without proper assessment can lead to wasted resources. Evaluating the specific training needs is vital to ensure the investment pays off.