Blog

Top Cooling Tower Tips for Efficiency and Maintenance?

cooling towers play a vital role in industrial and commercial cooling processes. According to Max Johnson, a renowned expert in cooling tower systems, "Efficient cooling towers are essential for sustainable operations." His insights resonate as companies strive for improved performance and cost savings.

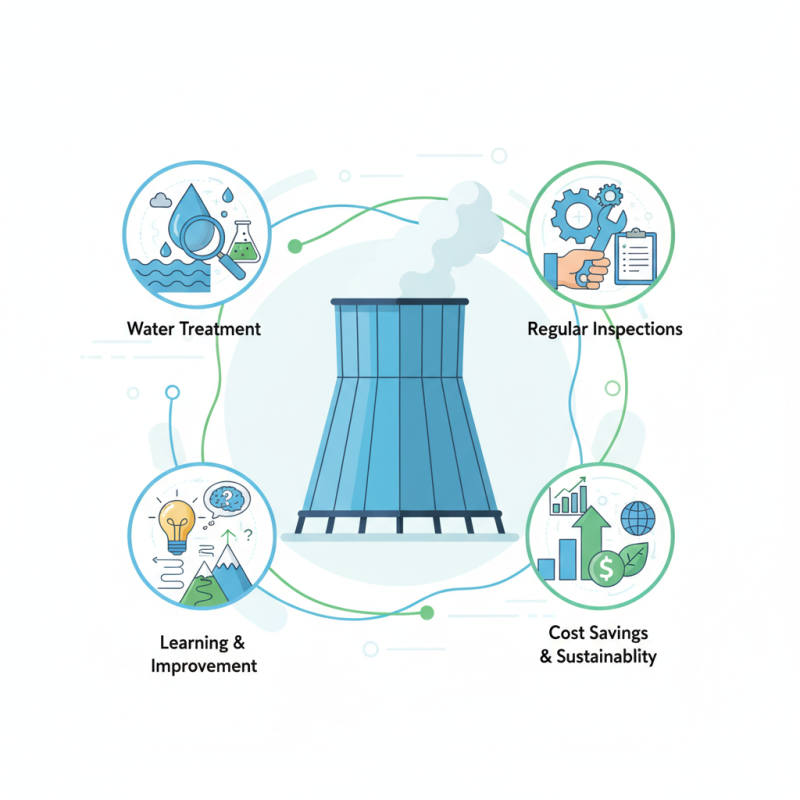

Maintaining optimal efficiency in cooling towers requires attention to various factors. Proper water treatment and regular inspections can prevent costly downtime. Neglected cooling towers can lead to energy waste and inflated operational costs, highlighting the need for proactive maintenance.

It's important to recognize that even industry experts face challenges with cooling tower systems. Learning from past mistakes can guide improvements. Assessing existing processes may reveal inefficiencies and areas for enhancement. In the pursuit of efficiency, companies must remain vigilant about their cooling tower operations.

Understanding the Role of Cooling Towers in HVAC Systems

Cooling towers play a crucial role in HVAC systems by dissipating excess heat. They facilitate the cooling process for equipment, ensuring optimal performance. According to industry data, efficient cooling towers can improve system performance by up to 30%. This shows their importance in energy management.

To maintain efficiency, regular inspections are essential. Inspecting for leaks, scale buildup, and obstructions can prevent costly repairs. Implementing a strict maintenance schedule significantly enhances longevity. A reliable report indicates that well-maintained cooling towers can last up to 20 years, maximizing investment.

Tip: Keep a log of maintenance activities. This helps track performance trends and identify issues early. Another tip is to ensure proper water treatment. Balancing chemicals in the cooling water can prevent corrosion and scaling. Regular monitoring is vital for effective operation. Remember, neglecting these practices can lead to inefficiencies and higher operational costs.

Key Factors Influencing Cooling Tower Efficiency

Cooling towers are vital in industrial settings. Their efficiency greatly impacts energy consumption and operational costs. Various factors influence how effectively they operate. Understanding these can enhance performance.

Water quality is crucial. It affects heat transfer and system longevity. High levels of minerals can lead to scale buildup. This reduces efficiency and may require costly maintenance. Regular water testing can help avoid this issue. Treating water properly is not optional; it is essential.

Airflow is another key factor. Blocked or dirty air intakes can hamper performance. Regular cleaning is necessary. Inspecting fan blades for wear is also important. If the airflow is not optimal, cooling towers struggle to release heat. This can lead to larger problems later. Keeping the system clean and well-maintained is not just good practice; it is vital for operational success.

Regular Maintenance Practices for Optimal Performance

Maintaining a cooling tower is crucial for its long-term efficiency. Regular checks can prevent issues that lead to costly repairs. Start with inspections every month. Look for dirt and debris that may clog filters. Even small problems can escalate quickly if ignored. Ensure the water levels are adequate. Low water can cause overheating, impacting performance.

Cleaning is another key practice. Scale buildup can reduce heat exchange efficiency. Use appropriate cleaning solutions. Pay attention to the fill media, as it can trap dirt. Don't forget to check the fan and motor for any signs of wear. Regular lubrication can extend their lifespan. Monitoring the temperature and pressure is essential, too. Anomalies might indicate larger issues ahead.

However, it's easy to overlook these tasks. Many operators face tight schedules. They might skip inspections or delay maintenance. This often leads to bigger problems down the line. Reflect on your maintenance routine. Are there gaps that need addressing? Emphasizing regular practices will ensure your cooling tower operates optimally.

Common Issues and Troubleshooting Techniques

Cooling towers play a crucial role in maintaining efficiency in HVAC systems. However, they can encounter several issues. Commonly, poor water quality leads to scale buildup. This can affect heat transfer efficiency. Regularly check the water chemistry. Balance pH levels and control minerals.

Another common issue is fan malfunction. A noisy or vibrating fan may indicate a problem. Inspect the fan blades for debris. Ensure that the motor is functioning properly. Addressing these problems early can save time and cost.

For optimal cooling tower performance, inspect the strainer regularly. A clogged strainer can reduce flow rates. Head pressure should be monitored, as well. If it's too low, consider cleaning the tower. Routine maintenance prevents unexpected failures. Small checks make a big difference.

Top Cooling Tower Tips for Efficiency and Maintenance

| Tip | Description | Common Issues | Troubleshooting Techniques |

|---|---|---|---|

| Regular Inspection | Conduct inspections every month to check for wear and tear. | Clogged filters, rust, leaks. | Clean or replace filters, inspect for rust and corrosion. |

| Water Quality Management | Monitor water treatment to prevent scale and corrosion. | Scaling, algae growth, corrosion. | Regularly test water and adjust chemical treatments as necessary. |

| Fan Operation | Ensure the fans are operating efficiently to optimize airflow. | Unbalanced fans, excessive noise. | Balance fans and lubricate bearings to reduce noise. |

| Regular Maintenance Schedule | Create a routine maintenance plan for parts replacement. | Component failure, inefficient operation. | Schedule regular service checks and replace worn components. |

| Energy Efficiency Monitoring | Track energy consumption to identify improvements. | High energy bills, inconsistent cooling. | Analyze energy usage data and optimize systems for efficiency. |

Best Practices for Enhancing Cooling Tower Longevity

Maintaining the efficiency and longevity of cooling towers requires a strategic approach. Regular inspections are essential. Studies indicate that consistent monitoring can reduce energy costs by up to 25%. Visual assessments can spot issues early. This practice prevents extensive repairs later.

Water quality plays a crucial role in cooling tower performance. Improper chemical levels can lead to scale formation and corrosion. Reports show that maintaining balanced water chemistry can extend tower life by several years. Regular water testing and treatment can also help in reducing microbial growth.

Cleaning is another critical maintenance practice. Debris buildup can hamper airflow and reduce efficiency. Research suggests that routine maintenance decreases energy consumption by 15-20%. However, many facilities overlook this step. Routine cleaning schedules should be a priority, not an afterthought.